Process of Creating Pure Silver Arts

Silver ore

Silver ore, acquired and prepared in accordance with Japanese Government Regulations.

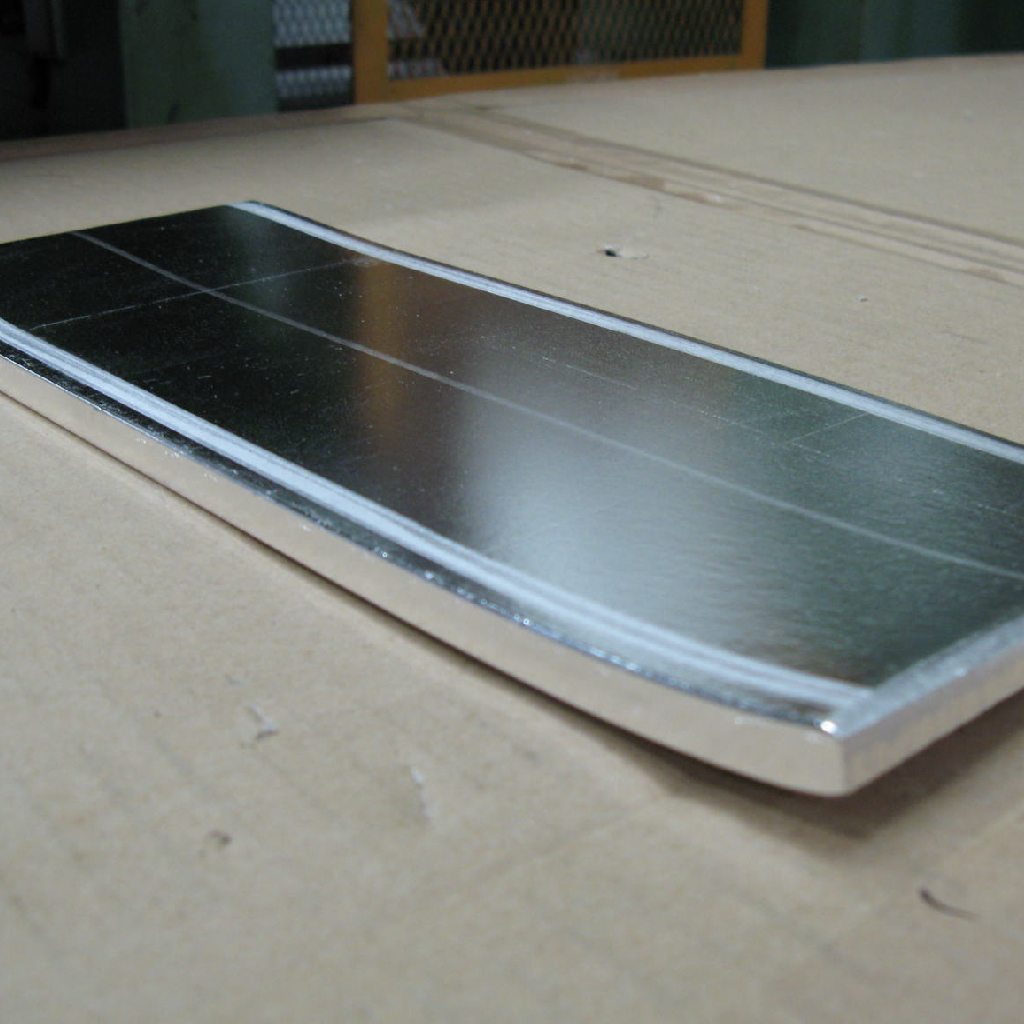

Smelting and pressing

The silver ore is melted and cast into a flat shape of about 1.5cm. This action is repeated successively until the silver is extended.

Traditional hammering tools passed down from 100 years ago.

We have all the necessary tools for our metalworks. You can feel the deep connection between the metalsmith and his tools, which plays an important role translating the artist’s feelings into art.

Fine adjustments

Our artists carefully weigh the silver, cut it to a circular shape and then delicately hammer out the creation.

Hammerforming

Our artists put the circular silver plate over an anvil (called a ‘kanatoko’), then start hammering the silver over and over again until it gets a ‘teapot form’

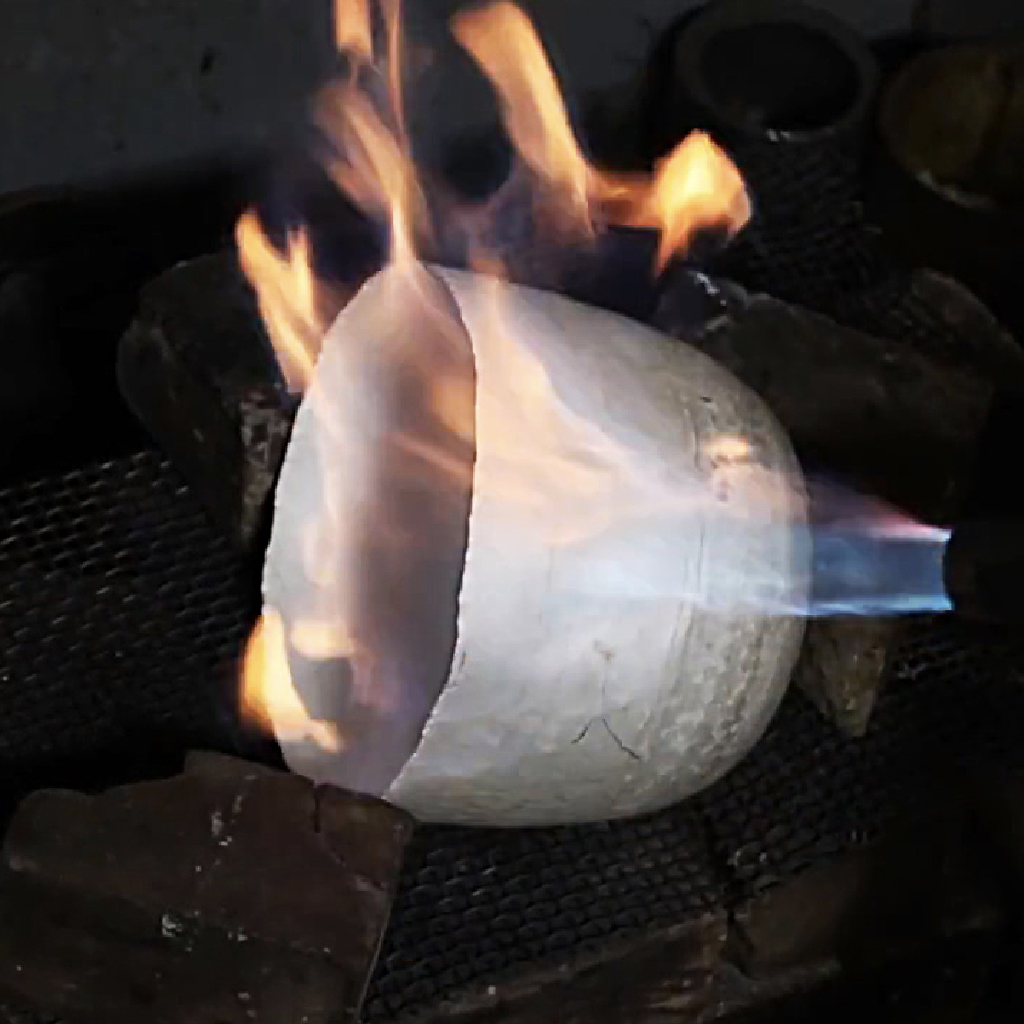

Adding malleability

When hammering the silver plate, it will gradually solidify and therefore become too hard to hammer. We must heat the silver in a fire to make it more malleable again. This process is repeated continually until the shaping is complete.

Hammering and forming

The casting from the original circular silver plate into the final ‘kettle’ shape requires a long continual process of hammering and softening.

Pattern hammering and processing

Our artists use different hammers to create different surface patterns. Each particular pattern has its own creation technique. In order to create a unique and distinctive silver kettle, it is necessary to focus on every detail. Each metalsmith has his/her own personal technique, which adds unique character and wonderful quality to their artwork.